Starting a BBQ charcoal production project offers an excellent opportunity to tap into the growing demand for high-quality, eco-friendly grilling fuel. The charcoal industry is thriving, driven by an increasing preference for outdoor cooking and sustainable products. This guide outlines the essential steps to successfully launch a BBQ charcoal production project, focusing on processes, equipment, and considerations for long-term success.

Understanding the Market Demand

Before embarking on a BBQ charcoal machine project, it is crucial to analyze market demand. The BBQ charcoal market is segmented into two primary categories: lump charcoal and briquettes. Lump charcoal is preferred for its natural composition and quick ignition properties, while briquettes are valued for their uniform size and longer burn time. Understanding these preferences allows for tailored production strategies that align with consumer needs.

Conducting market research is essential. Identify potential customers, including retailers, restaurants, and individual consumers. Analyzing competitors provides insights into pricing strategies, packaging options, and marketing techniques. This foundational knowledge helps shape the business model and informs decisions throughout the production process.

Sourcing Raw Materials

The choice of raw materials is pivotal in determining the quality of the final product. Coconut shells are increasingly favored for BBQ charcoal production due to their high carbon content, low moisture levels, and availability as a byproduct of the coconut industry. To understand how to make charcoal from coconut shell, it is essential to recognize the properties that make it suitable for carbonization.

Establishing reliable sources for raw materials is vital. Engage with local suppliers or agricultural producers to secure a consistent supply of coconut shells. Forming partnerships can enhance supply chain reliability, ensuring uninterrupted production and minimizing costs.

Selecting the Right Equipment

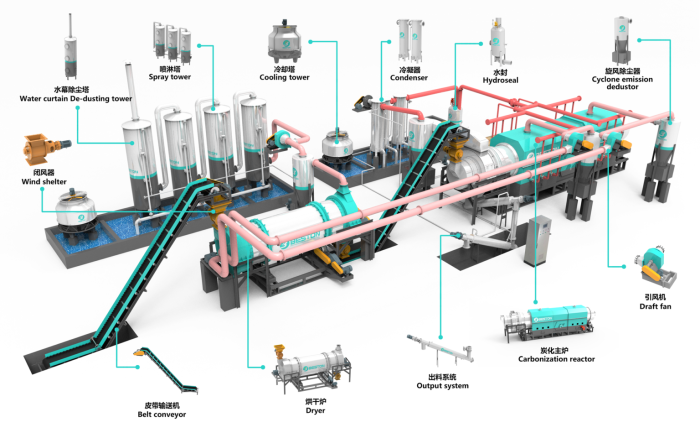

Investing in the appropriate machinery is crucial for the efficiency and quality of BBQ charcoal production. A charcoal machine designed for coconut shell processing is essential. Modern machines facilitate the carbonization process, converting raw coconut shells into charcoal through pyrolysis. This method not only ensures efficient conversion but also captures byproducts such as syngas, which can be used to fuel the process, enhancing overall energy efficiency.

When selecting a charcoal machine, consider the production capacity, automation level, and maintenance requirements. It is advisable to choose a reputable biochar machine manufacturer known for producing reliable, high-performance equipment. Researching various manufacturers helps identify options that meet production needs while providing technical support and warranty services.

Setting Up the Production Facility

The production facility’s layout and design should prioritize efficiency and safety. A well-organized space allows for smooth workflow, from raw material storage to the final packaging of charcoal products. Key considerations include:

- Location: Choose a site close to raw material sources and transportation routes to facilitate logistics.

- Storage: Allocate areas for storing raw coconut shells and finished charcoal. Proper storage minimizes moisture absorption and preserves product quality.

- Safety: Implement safety measures to address potential hazards associated with carbonization, including fire risks and emissions control.

Implementing Quality Control Measures

Quality control is vital in ensuring that the final charcoal product meets market standards. Establishing protocols for testing and evaluating the charcoal’s properties—such as ash content, calorific value, and moisture level—ensures consistency and reliability. Regular inspections of the production process, coconut shell charcoal briquette machine maintenance, and staff training contribute to maintaining high-quality output.

Engaging with customers for feedback can also inform improvements. Listening to consumer preferences and adjusting production accordingly can enhance customer satisfaction and loyalty.

Marketing and Distribution Strategy

Once production is established, developing a marketing strategy is essential for promoting the BBQ charcoal brand. Consider various channels, including social media, online marketplaces, and local retailers. Highlight the unique selling points of the product, such as its eco-friendliness and superior burning characteristics.

Establishing partnerships with local retailers and distributors can facilitate market entry and enhance visibility. Participate in trade shows and community events to promote products and engage with potential customers. Building a strong brand identity can differentiate the product in a competitive market.

Financial Planning and Funding

A comprehensive financial plan is critical to the project’s sustainability. Outline initial capital expenditures, operational costs, and projected revenue. Identify funding sources, such as personal investment, loans, or grants tailored for sustainable businesses. A well-structured financial plan not only helps in managing cash flow but also aids in attracting potential investors.

Conclusion

Launching a BBQ charcoal production project involves careful planning, from understanding market demand to selecting suitable equipment. By focusing on sourcing quality raw materials, investing in an efficient charcoal machine, and establishing effective marketing strategies, entrepreneurs can successfully tap into the booming charcoal market. With the right approach, a BBQ charcoal production project can evolve into a sustainable and profitable business venture, meeting the growing consumer demand for eco-friendly grilling options.